Recycling heat. Saving energy costs. Reducing CO2 emissions. With industrial heat pumps made by SPH.

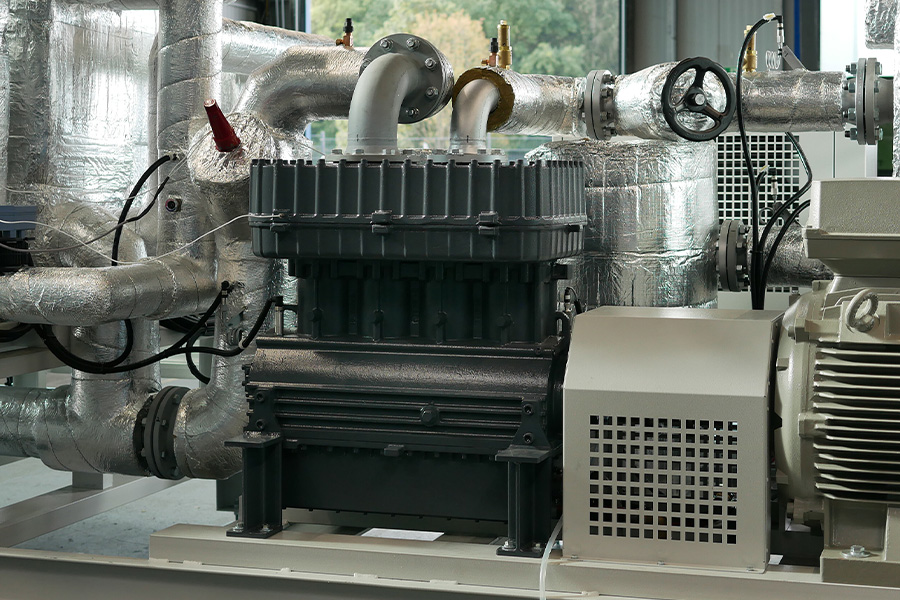

Thermbooster™ from SPH Sustainable Process Heat

SPH develops solutions for the future. Our industrial heat pump makes you independent from fossil fuels, lowers your energy costs and helps to protect our climate.

Our ThermBooster™ heat pump generates temperatures of up to 165 °C and in future, in excess of 200 °C. A high-temperature piston compressor, designed specifically for this purpose, combined with innovative process technology is making this a reality.

Benefits

The SPH ThermBooster™ industrial heat pump is a unique high-temperature heat pump solution.

Our industrial heat pump can be used in a wide range of industries, applications and industrial processes. Reduce your CO2 emissions and energy costs and increase your energy efficiency. This is how you benefit when you use our ThermBooster™ heat pump:

Environmentally compatible

Reduction of primary energy demand and energy costs

Cost-effective

Cost-effectiveness achieved through energy-efficient processes

Zero emissions

100 per cent CO2-free process heat when green electricity is utilised

Non-dependent

Elimination of dependence on fossil fuels

Uncomplicated

Easy incorporation into existing production environments

Proven

Proven technology dating back more than 30 years

Environmentally compatible

Reduction of primary energy demand and energy costs

Cost-effective

Cost-effectiveness achieved through energy-efficient processes

Zero emissions

100 per cent CO2-free process heat when green electricity is utilised

Non-dependent

Elimination of dependence on fossil fuels

Uncomplicated

Easy incorporation into existing production environments

Proven

Proven technology dating back more than 30 years

Seeing the challenge of climate change as an opportunity

Climate change is confronting companies with major challenges, yet is also providing the opportunity to make processes more sustainable. We started out with the vision of reducing energy consumption and CO2 emissions in production processes.

Solutions for the future

We harness our automotive and refrigeration technology expertise to help you incorporate our heat pumps into your production environment.

We provide you with specific advice and support throughout the entire project process up to commissioning. We also provide you with service, maintenance and remote monitoring support.